Types of roof trusses can be classified in many ways. Their primary structural support members are the most common way, known as chords, beams, or arches.

Roof trusses are components that transfer the weight of a roof to vertical load-bearing walls. Different types of roof trusses exist for different styles and designs of buildings. Roof trusses can also be classified based on the kind of member connections they use, such as wood joinery methods like slide-lap, mortise, and tenon joints. Additionally, some trusses are classified as either heavy-duty or light duty, depending on the loaded weight they must carry.

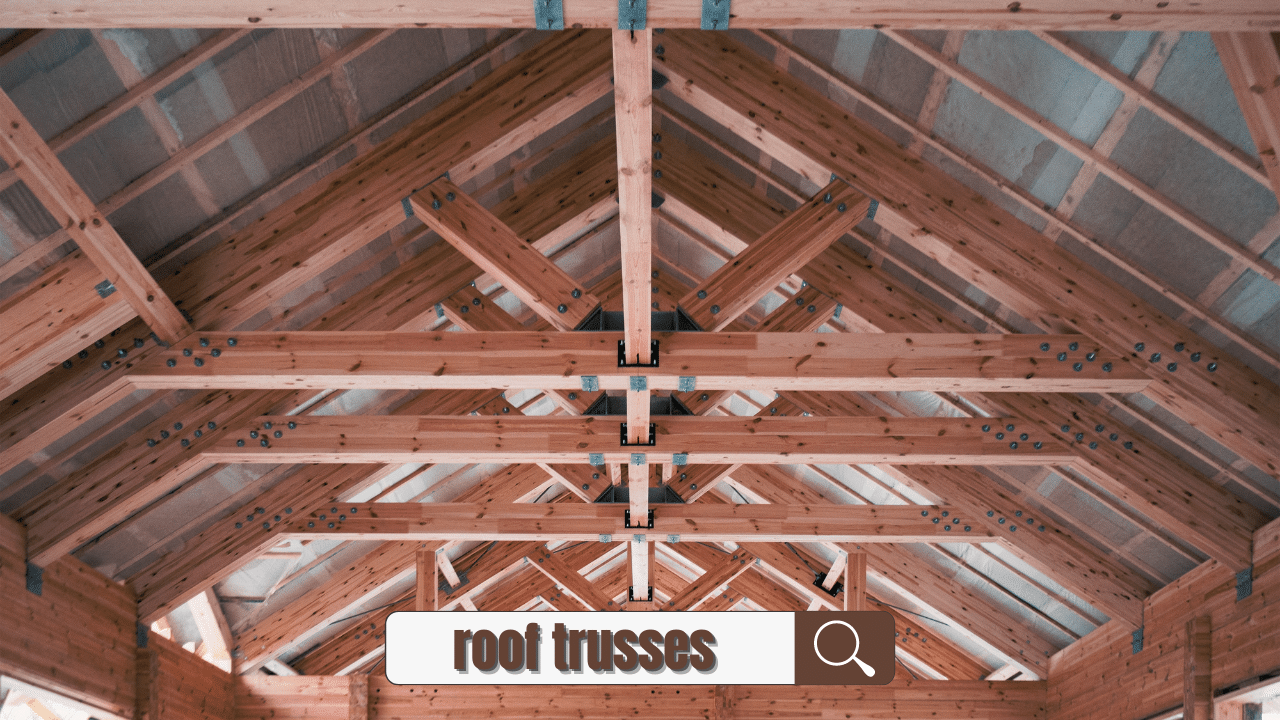

In this article, we will explore the common types of roof trusses used in residential construction today. While we can find these roof truss types on various structures, we will focus mainly on their use in home construction.

Common Types of Roof Trusses

Roof trusses are structures used to hold up the roof of a building. They are made out of metal or wood and can either be heavy or light. Roof trusses must be able to meet specific state regulations to prevent accidents at construction sites. The types of roof trusses depend on its function and how it is used in building. (Related: Outdoor Kitchen Cost & Consumer Guide)

The following are a few common types of roof trusses:

T-Truss

The T-truss has a horizontal top chord and sloping diagonal bottom chords, which form a “T” shape, hence its name. T-trusses provide support for the ridge of the building due to their strong triangle shapes. They can also go in vertical positions when they are needed. This type is most common in construction sites because it supports roofs that span large areas or extended heights. It is also easy to install and requires basic carpentry knowledge.

Tee Truss

These types of trusses look like T trusses, except they are open at one end. They are great to use when it is difficult to set up T trusses because they fit through narrow spaces and small openings. Tee trusses allow more light to enter the building since there is no solid horizontal beam, allowing plenty of ventilation.

Caterpillar Trusses

These consist of two sections that can use separately or together depending on what the designer plans. The first seduction is composed of two parallel chords with purlins connecting them. This part can be used as a separate unit without the top chord attached, unlike T-trusses (which need all the three parts together).

The following article explains the main differences between 3 main types of roofs: cathedral, shed, and hip or monitor style roofs.

1. Cathedral Style Roof Trusses

Cathedral-style roofs feature four slopes on each side called gables and a ridge running down the middle called a ridge board. In addition to those two components, it features purlins all around its edges and one in the middle of each roof. Finally, a collar tie is added to connect the ridge board to a purlin at a given corner.

The cathedral-style roof is the most common type of truss based on its ability for a wide range of pitch and span. Put in another image if necessary to help break up the text. Unlike cathedral roof trusses, shed roofs feature a ridge running down the middle called a ridge beam, with two slopes on each side called gables. The rest of the truss components are similar to a cathedral-style roof, including purlins, a collar tie, and rafters.

2. Shed Style Roof Trusses

Shed-style roofs also feature gables but only have purlins on their edges. It does not have a ridge board or a collar tie connecting from its ridge board to one of the corners. Instead, it connects directly to horizontal beams at either end called plates. Unlike cathedral roof trusses, shed roofs feature a ridge running down the middle called a ridge board and purlins only on the sides of the top. One plate is at each end of the ridge board, truss type, and one directly above the plates.

It features a gable per side as well as a roof per corner. Although it is simpler than a cathedral-style roof, the shed-style top can only work with a small span and a very shallow pitch. However, it will have fewer truss components to keep track of than a cathedral-style roof. To summarize, a shed-style top features a ridge beam running down the middle with just the two main slopes on each side facing outward. The rest of its truss components are also very similar to those found in a cathedral-style roof.

3. Hip or Monitor Style Roof Trusses

Hip-style roofs feature four slopes on each side called hips, with a valley in between every two. It also has horizontal beams called plates that connect from hip to hip across its width. Each hip ends at an intersection with a ridge board called a ridge cap. To finish off this roof type, collar ties are added within the corners of hips and ridges to help stabilize it.

In addition to different roof truss styles, there are also other types of wood for trusses. Hip and monitor roof styles are similar with regards to their truss systems. They both feature two slopes per side for an even appearance. Furthermore, they use purlins, plates, and rafters to create their structure.

Wood Truss Types

Traditionally, wood was used as primary structural support for roofs because it is inexpensive and accessible to many builders. Wood Roof trusses were engineered by early pioneers and gained popularity throughout the mid 20th century. Wood Roof trusses have been known to last up to 70 years if properly maintained and cared for during that time.

Over the last few decades, wood roof trusses have been slowly but surely replaced by engineered steel trusses. Structural engineers now prefer to use metal roof truss designs to carry more weight, span greater distances, and provide superior structural stability. The following are several common types of wood roof trusses that are used in home construction today.

Solid Sawn Trusses

Solid sawn trusses are made from one type of lumber cut into specific lengths. This ensures that all members have the same properties since they're coming from the same tree. They're generally not made to order and instead come in predetermined sizes.

These tend to be simpler than glued laminated or manufactured roof trusses, making them easier to install on-site but limiting some flexibility.

Glued Laminated Trusses

Glued laminated trusses are made up of different types of wood glued together and then cut into specific lengths. Glued laminated trusses contain beams of multiple layers (usually two) called laminations pressed together under high pressure with adhesive between each layer.

They are made with structural composite lumber, the same material used to make beams for some bridges.

This truss type can be ordered due to its multiple laminations but must follow particular standards to qualify as a glued laminated truss. The benefit to this type of truss is they accommodate unique properties across different types of wood. The disadvantage is that they're significantly more expensive than solid-sawn trusses.

Manufactured Trusses

Manufactured trusses are produced at a factory with machines, molds, or robotic arms that cut the wood into predetermined lengths without regard to grain or properties of the lumber. These are often ordered from an engineered design and offer more flexibility than solid-sawn trusses because machines create them.

Manufactured trusses are built from different wood types and pieces that are cut to be identical. They're the cheapest option for building roofs but may not be as sustainable or consistent to build.

Now you know the basics of different types of roof trusses and their components and variations. If you want to design your trusses for a specific roof, keep reading. When you're planning a new building, the engineer will take into account the design of the building, load calculations for structural pieces like trusses, and regional weather patterns. This will allow them to determine what type of roof truss will be best suited for that project.

Common Rafter Trusses

These are the most basic style of roof truss design. These are also known as "standard duty" or "light duty" trusses because they do not span very far and cannot support much weight. This type of rafter is commonly found in tiny homes or homes with limited square footage. Standard rafter trusses are engineered to bear the weight of only their end walls, not exterior walls.

The spacing between common rafters varies by region and depends on many factors, including weather conditions, snowfall amounts, and soil compaction. For example, in dry climates where snow may not accumulate much or at all, they can be spaced 24" apart. But in wetter climates where there is potential for greater snow accumulation, 16" oc is more appropriate. It's important to note that the span distance of this type of roof truss usually ranges from 6' - 10' maximum.

Listed below are the Common Rafter Truss types:

Box-frame Trusses

These have a smaller footprint than other types because they do not have any vertical posts placed between the rafters. This truss-type Russ is typically used on homes with limited space, such as sloped roofs or houses built on small building plots.

Box frame trusses are often glued together during the construction process to form a rigid roof structure. The bottom chord of each truss usually consists of 2×8 lumber, which gives them good resistance against out-of-plane wind loads. They also have greater spans than platform trusses, making box-frame trusses suitable for flatter regions with strong winds.

Platform Trusses

These consist of several horizontally stacked rafter sections with horizontal blocking between units for lateral support and stability. These types of roof trusses typically have a length of 32' maximum. Two 8' long 2×8 beams are used on the bottom chord, which provides good out-of-plane resistance. The spacing between roof trusses can vary depending on climate and area of distribution.

Platform trusses are commonly made by combining two or more common rafters into one structural unit (glued box) during construction. These types of trusses are placed in a stacked arrangement to provide the necessary support to the structure. Platform trusses have greater spans than box-frame trusses, making them suitable for flatter areas with strong winds.

Sheathed Rafter Truss Types

These types of roof trusses are similar in appearance to common rafters but are much more significant. This truss can span up to 20', which is twice as long as common rafters. With the comprehensive span capability, the load capacity of sheathed trusses increases significantly.

Typically, 2×6 or 2×8 lumber is used for this type of roof truss. Sheathed trusses generally are kept at 16" oc on center, which provides adequate spacing between them to provide stability and lateral support. Because of their superior strength and light-duty designs, sheathed rafter roofs are often exposed above the interior ceiling surface. Trim pieces can be added around the exterior perimeter if desired.

Framed Rafter Truss Types

Trussed (or framed) rafter trusses are engineered to support exterior wall cladding and interior ceiling weight. Framed rafter trusses consist of several standards or sheathed roof trusses interconnected by metal plates and girts, which provide added lateral stability.

Framed roof trusses can be spaced 16" oc on center or 24" oc on center, depending on the span. Framed rafter trusses are suitable for various roof slopes and span lengths but generally have a maximum height of 30'.

Framed roof trusses can be spaced 16" oc on center or 24" oc on center, depending on the span. Framed rafter trusses are suitable for various roof slopes and span lengths but generally have a maximum height of 30'. By using an engineered rafter truss, you can improve the strength and durability of your roof.

SIP (Structural Insulated Panel)

Structural insulated panels (SIPs) provide a rigid form for various types of panelized construction. SIP trusses also offer a wooden structure to multiple panelized construction units (glued boxes) during construction. These types of trusses are placed in a stacked arrangement to provide the necessary support to the structure. Platform trusses have greater spans than box-frame trusses, making them suitable for flatter areas with strong winds.

Depending on the manufacturer, SIPs are categorized as either Rastra or Smart-Raft. Typically, SIP trusses consist of several different types of insulation that provide specific benefits to the structure. For example, polyisocyanurate foam offers high thermal resistance making the SIP trusses ideal for low-energy savings regions. When it comes to fire, certain types of insulation are more suitable, such as rock or slag wool which has high durability and self-extinguishing properties.

Both Rastra and Smart-Raft provide lateral stability between the rafter trusses via girts. Framed rafters are typically used to reduce the number of girts and trusses needed in a given structure, making SIP roof trusses more efficient.

About Roof Trusses

Roof trusses support the weight of exterior wall cladding and interior ceiling, making them sturdy and stable.

Typically, 2×6 or 2×8 lumber is used for this type of roof truss. Framed rafter trusses generally are kept at 16" oc on center, providing adequate spacing between them to give stability and lateral support.

Conclusion

To conclude this article about roof truss types, it is essential to mention that each style has pros and cons. That simply means it is up to the building owner or worker to decide the truss type that works best for the projects and budget. You can do this by consulting with general contractors who have extensive experience with roofing projects.