An electrical conduit is used to run electrical wiring through to protect it from external influences such as impact, vapors, moisture, and even from being chewed on by animals.

When running electrical underground, you will need to decide on what conduit to use. Therefore, it’s essential to review your requirements, including the environment where the conduit will be installed and the timing and costs of your project.

Different types of conduit work better in different environments, and you’ll find that the installation time and skill required will vary. There is little point in spending a lot of time and money on conduit that you don’t need. However, if you install the wrong type of conduit, you may be digging it up later, which involves even more time and cost.

So, what conduit options do you have, and what are the advantages and disadvantages of them?

Advantages of Using Electrical Conduit

Do you even need an electrical conduit? No matter what option you choose, installing conduit adds time and cost to your project, so installing it in residential areas may not be required, though this would be advice for electrical wire in walls. (Related: HVAC Options To Control The Heating & Cooling of Your Sunroom) There is some underground wiring you can run without conduit, Direct Burial rated wire, but you will need conduit if your wiring is not rated to be buried underground.

Consider these advantages to see if you really need to install conduit.

What Types of Conduit are Available?

There are two broad types of conduit, metal conduits, and non-metal conduits. The difference between conduit is how thick the walls are, the material’s stiffness, and what the material is made of.

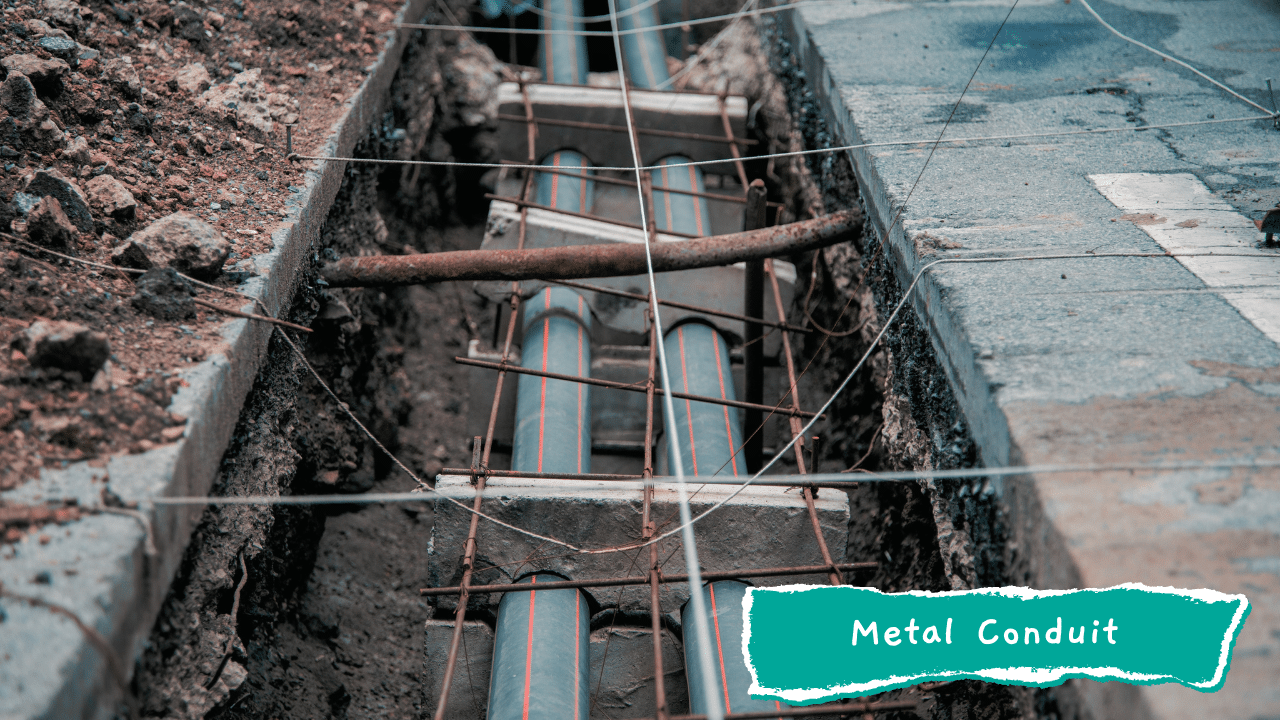

Metal Conduit

The metal used can differ but is generally stainless steel, galvanized steel, or aluminum. If a different type of metal is being used, you need to determine the reasoning or if this is appropriate for your needs.

Rigid Metal Conduit (RMC)

Rigid metal conduit has exceptionally thick walls and is best suited where impact or damage is a significant possibility. The thick walls are also suitable where electromagnetic interference is possible, which is often a problem with sensitive equipment.

RMC will need to be coated with some type of corrosion-resistant material to protect it from corrosion, which adds additional cost to the product.

The two significant issues to consider when using this type of conduit. First, the material is threaded, so it is labor intensive to install, which adds even more to the cost. Second, the material is very heavy, so the cost and time involved in installing it are also higher.

Electrical Mechanical Tubing (EMT)

Electrical mechanical tubing is generally made of coated steel or even aluminum. It is almost half the weight of many RMC products making it cheaper and easier to install.

EMT protects wiring from some damage, but the walls are relatively thin, so the cost savings result in a less protective conduit, which is not ideal where the risk of damage is high.

If the conduit is used near moisture or vapors, you need to use special EMT, which starts adding to the cost, and RMC may be a better option depending on the price.

Intermediate Metal Conduit (IMC)

Intermediate metal conduit has walls thinner than RMC but thicker than EMT, so it’s a reasonable option to use where you want cost savings but still need to protect from expected damage to the wires from impacts.

The material is often made from steel and can be coated to suit your environmental needs.

Flexible Metal Conduit (FMC)

As the name suggests, a flexible metal conduit provides flexibility in the conduit to be easily maneuverable instead of going in straight lines. You can get FMC in different wall thicknesses depending on your needs and risk of impact to the wires.

FMC should only be used in dry areas unless you get liquid-tight flexible metal conduit (LFMC), which is just FMC with a waterproof coating over it.

LFMC is best suited where you need to embed the conduit underground, as well as in concrete. LFMC comes in many versions that protect against different factors, including extreme heat, oil resistance, anti-bacterial, flame resistant, and even reinforced for added impact protection.

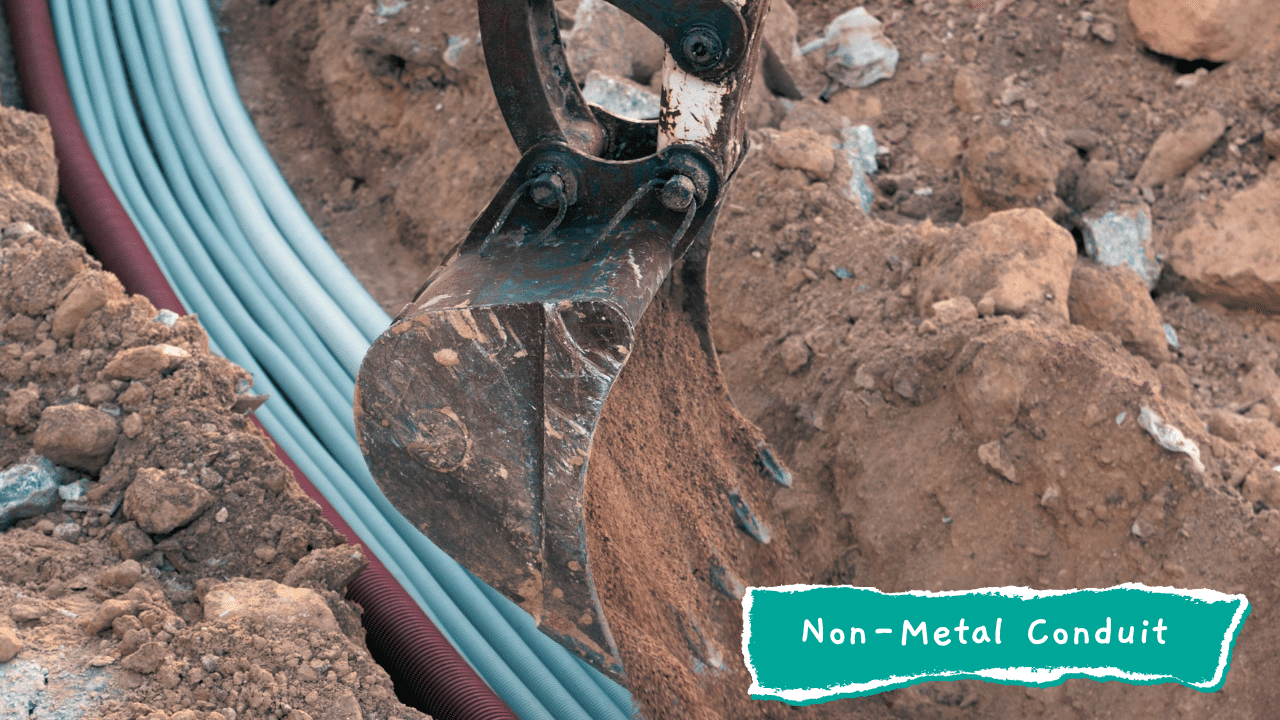

Non-Metal Conduit

Non-metal conduit is most often made of PVC and is best suited when it will be used underground, in concrete, or exposed to a lot of water. Non-metal conduit cannot be used as a redundant ground conductor, so it may not be possible in your project. You would need to review local codes to see if they can even be used.

Rigid Non-metal Conduit (RNC)

Rigid non-metal conduit is the lightest and least expensive option. You can weld the joints to make them waterproof, and the material can also be heated so that it can be bent easily when you need to maneuver it outside of straight lines.

The biggest issue with RNC is that it will not be resistant to impact as well as metal conduit. So high-impact or areas with potential damage would not do well with RNC.

Electrical Non-metal Conduit (ENC)

Electrical non-metal conduit is much easier to bend and maneuver than RNC, making it easier to install; however, you need to hold it in place as the bends will not hold by themselves. The walls are also relatively thin, so they are not ideal for high-impact areas.

ENC is not water-resistant, so it is not suitable for wet areas. However, you can get a more expensive option, liquid-tight flexible non-metal conduit (LFNC), which can be made water-resistant.

Both options are limited impact resistance, so they are best suited where minimal protection is needed, but the flexibility of the conduit is a significant factor.

Final Thoughts

As you can see, there are various options available for conduit, and depending on your environment and project budget, you will need to decide what factors you need most. For example, you can go for light and easy-to-install options that provide minimal protection but the ease of replacement of wires.

However, if your environment has a high chance of impact and the wiring is critical, you will need to go for heavier and more costly metal options or risk future problems with electrical disruption due to damage.