Have you ever heard of the quote "Great things are done by a series of small things brought together." by Vincent Van Gogh? He used it to describe the process of how people experience successes in life, but conveniently enough, the saying applies to home construction, too.

The smallest of construction tools and materials make up the whole house. From nails to bolts (and the subject of our article today, screws), though these parts may not be much to look at, they are literally the reasons why things are kept together in a structure or a home. For screws they can hold together a wooden seat, cupboard, or hang your family photo on the wall.

But don't be mistaken! Though all screws may seem functionally the same, there are actually various types of screws that are scattered across your local Home Depot that serve specific purposes, and we're going to tackle the NINE most common screws that builders use for home construction.

What is a Screw?

Screws are the most ubiquitous fastener in the world, with helical threading wrapped around a long shaft. Screws are frequently used to link two or more solid items. In a way, they provide a simple and effective way to connect numerous solid objects. However, while all screws are characterized by helical threading around the shaft, they aren't all the same. (Related: Plumbing Terms Every Homeowner Should Know When Remodeling Their Bathroom)

When do you Use a Screw?

Screws are a popular fastener among woodworkers because they may be used to make jigs (temporary constructions that guide and keep work steady) for minor jobs like hinge installation. Screws can also be used to install hardware and trim, build cabinets, and unite furniture components, such as a tabletop to a base. Alongside this, screws are also preferred when working with more fragile materials like plaster and drywall because they generate less vibration—and hence less possible damage—during insertion.

In terms of tensile strength, which refers to the ability of objects to resist breaking under pressure, screws are also preferable for applications like porch railings or kitchen cabinets wherein corresponding parts are under stress or carrying weight. In conclusion, screws are your go-to fastener if your aim is long-lasting stability

Nine Most Commonly Used Screw Types in Home Construction

1. Wood Screws

A wood screw is a type of screw with coarse threads that tightly hold the wood. When connecting wood to wood, this screw provides a tight bond. The threaded tip grips the bottom of the board as you screw it in, and it maintains to do so until the two pieces of wood are securely fastened together. In that, the smooth portion of the screw will not hold the wood and will instead spin until the screw is flush with, or just below, the wooden surface. Thus, it reduces splintering.

Visually, wood screws are preferred because their heads can be flat, oval, or circular. With this, it is recognized that flatheads are essential fasteners for situations where screws must be concealed or sit flat against the wood surface. (i.e., on furniture.)

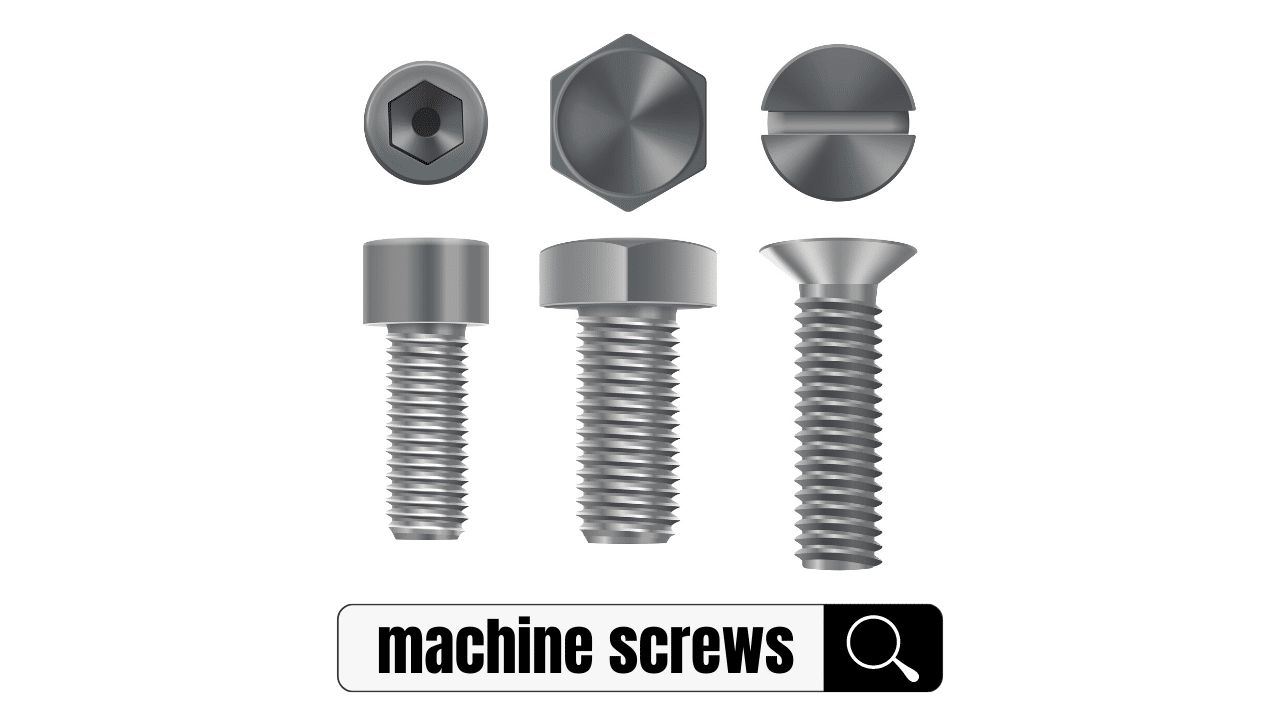

2. Machine Screws

A machine screw is a screw that is utilized in machining operations, as the name indicates. Machine screws come in a variety of shapes and sizes, and a stove bolt is one of them. Heavy-duty metal items are held together using machine screws. Machine screws often have a diameter of 0.75 inches or more, making them larger than most ordinary screws.

One thing to keep in mind about these screws is that they have a blunt head and are frequently used to connect plastic and metal. As a result, never use them as a substitute for wood screws since they will ruin your material.

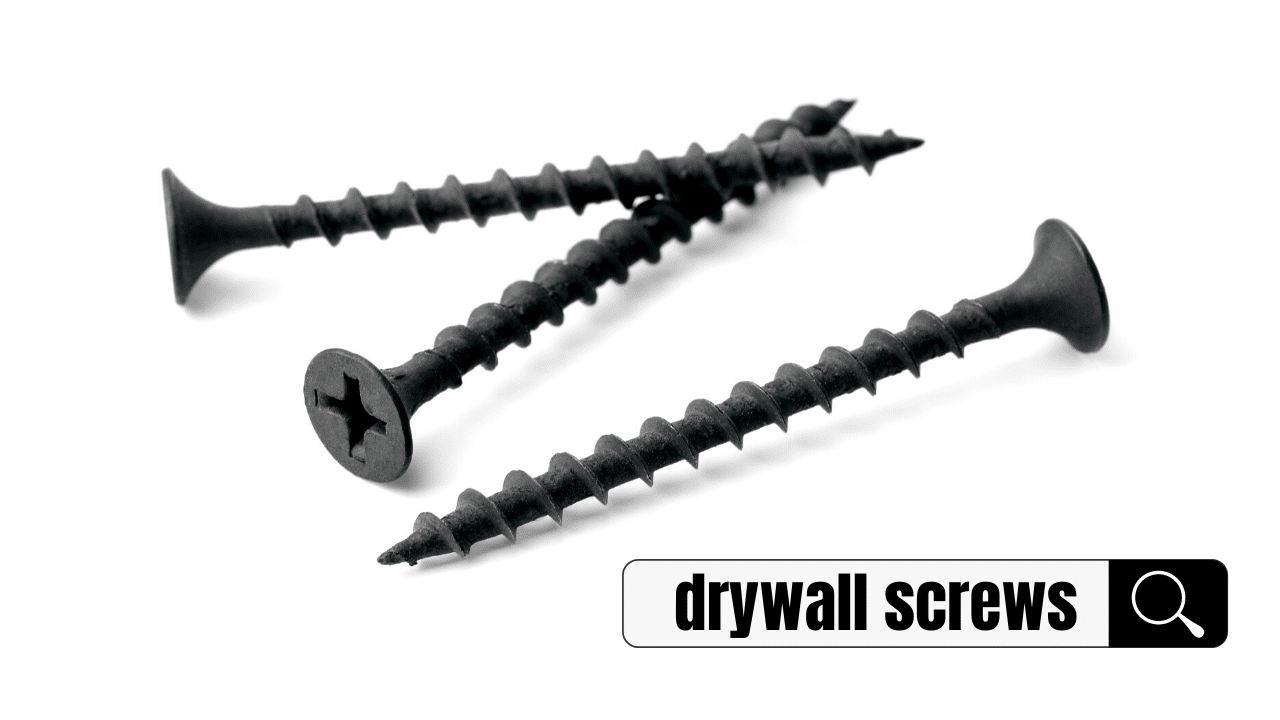

3. Drywall Screws

Drywall screws perform precisely what their name implies: they fasten drywall to joists or wood studs. These screws come in sizes ranging from one to three inches, and they need the use of a drywall dimple to be able to install them. In a way, because drywall screws dig straight in when they reach the studs or joists, which implies that you won't need to predrill any holes to put these screws in place.

But before you go buying these screws, it is crucial to note that if you're going to use these screws to connect drywall to metal studs, you'll need to purchase drywall screws that say they're suitable for that specific use.

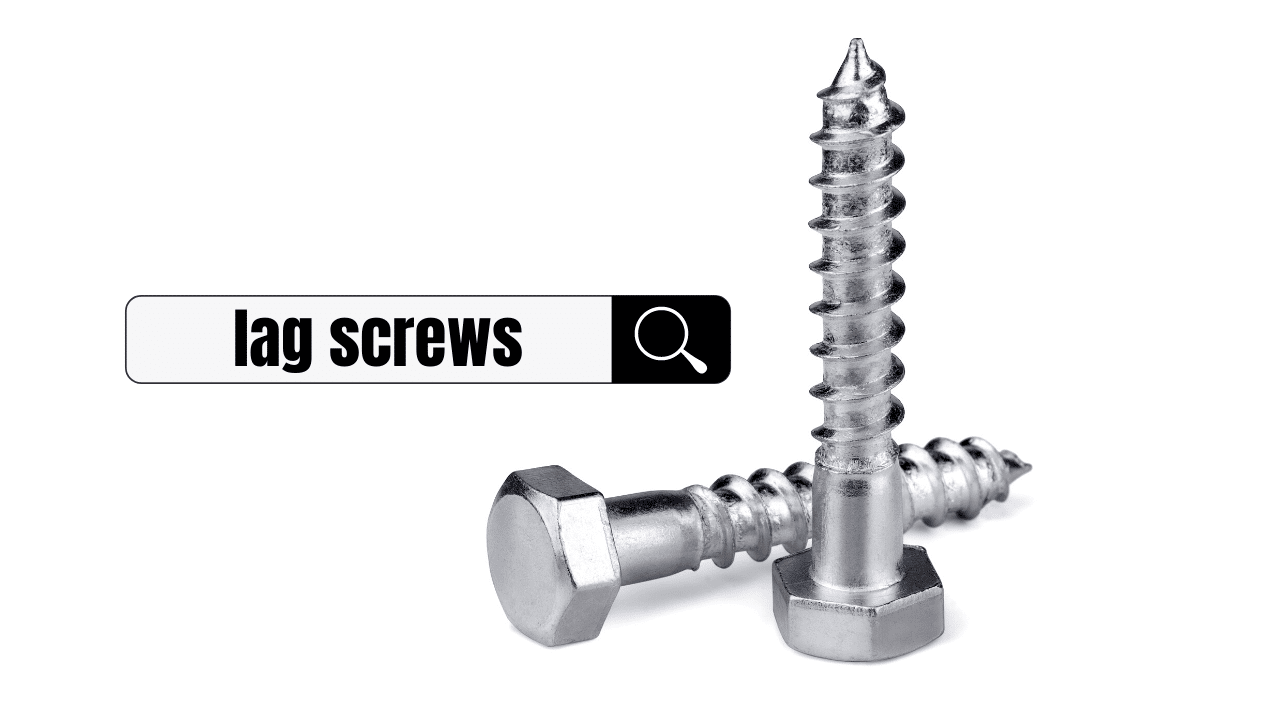

4. Lag Screws

So, what is a lag screw? Lag screws, also known as lag bolts or coach bolts, are simply jumbo-sized wood screws coated with zinc. Because they are widely used, these screws have a zinc coating that protects them from rust and corrosion. They are commonly used for outdoor projects such as playgrounds, fences, and garden objects. Most of the time, you'll want to add a washer beneath the head to improve the strength and aesthetics of the final assembly.

5. Decking Screws

Decking screws are primarily used to secure a deck's flooring to the joists. These screws are comparable to wood screws, except they are self-tapping and come in star-drive and Philips’s head varieties. As to which decking screws you require, it will mainly be determined by the type of decking material you select. While pressure-treated wood necessitates the use of an ACQ-compatible decking screw, composite decking materials frequently need the use of stainless-steel decking screws.

Simply put, the most typical application of decking screws is to install or connect outdoor decking or deck flooring to a joist structure. As a result, these screws are intended to countersink, which means they rest flat or just below the surface of the board.

6. Masonry Screws

Masonry screws, often known as anchors, have a distinctive appearance that sets them apart from other types of the screw because they don't have a bottom tip, and some of them will require a hex-head bit rather than a Philips head bit. To use them, holes must be predrilled before inserting and fastening these screws, which are used to attach metal or wood to concrete.

A lot of masonry screws are self-tapping screws that may be used in concrete, brick, mortar joints/block, and CMU, among other materials.

7. MDF Screws

Medium-density fiberboard (MDF), which makes up a significant percentage of the inside trim of homes and constructions, is often secured with MDF screws. Ordinary screws will shatter medium-density fiberboard, which is harder than solid wood. While regular wood screws may be used by simply predrilling all your holes, obtaining and using MDF screws will save you a lot of time.

Because MDF consists of a substance that is tougher than real wood and more difficult to puncture, these screws are exceptionally robust. Unless you predrill a hole and then use a regular wood screw, using wood screws on MDF will almost always result in splitting.

8. Concrete Screws

Concrete screws have a unique thread and a high-strength coating that allows them to grip concrete and other building materials. These screws come with two different types of heads. The hex head is best for surface installation, while the flathead is best for flush installation.

Concrete screws are a fast, simple, and extremely powerful approach to fasten to concrete. And, best of all, no hammering, anchoring, or shielding is necessary. All you have to do is drill a hole and screw the screw in.

9. Twinfast Screws

Twinfast screws have a one-of-a-kind design with two threads instead of one. When compared to ordinary screws, they can be driven twice as fast into things since they have twice the threading. The coarse thread, which has two times the thread pitch of standard wood screws, making it simple to drive them into various densities of chipboard, particleboard, and fibreboard.

They may also be readily inserted with standard drive bits and hand screwdrivers due to their large thread. Its self-centering tip also aids in straightening the screw and reducing the possibility of chipboard breaking.

Things to Consider Apart from the Type of Screw

Identifying what type of screw, you need for your construction project is only scratching the tip of the surface; there are two other major considerations that you need to take to pick out the perfect screw that meets your needs:

Size of the Screw

The size of the screws varies depending on the kind, although many of them come in a variety of sizes. Screws are measured in length as well as gauge or diameter. At the store, you will commonly see screws for wood are scaled by two numbers: the first is the screw's gauge, which is its diameter. This indicates that the diameter increases as the number increases. As a result, a screw with the number 12 is bigger than one with the number 4. So, the kind of screw determines how the length is determined when measuring the length of a screw.

Any screw that is flush or slightly beneath the material when screwed in has a length that involves measuring the whole screw. For example, the length of sheet metal screws and lag screws, the two most common screws with a head on the material's surface, is determined by measuring from the screw tip to just under the screw head.

Type of Thread

A screw's thread is a helical shape that goes around the screw's cylinder. It transforms rotational movement into linear movement and can contain several variations, such as the thread's shape, angle, and pitch (the distance between each thread's crests). In a way, each of these subtle and minor features can have a significant impact on the screw's performance and uses. While knowing the different screw kinds and sizes is helpful, but you'll probably need to know a little about screw threads as well to correctly choose the right screw for your project.

When it comes to the types of threads that many screws have, they are categorized in a few different ways. Sometimes you will see screws labeled by the number of threads per inch or the distance between each thread. However, you will mostly see them labeled as coarse, which are deeper threads, and fine, which are threads that are closer together and not as deep.

Importance of Knowing the Types of Screws

Screws are made with the materials they'll be used within the mind. Although using a drywall screw to secure a piece of wood is doable, it isn't always the ideal option. There are a variety of reasons why selecting the right screw is critical. Furthermore, after knowing everything, you can now assume that using the wrong size or kind of screw can really "screw" things up.

Particularly, there are four reasons as to why you must be keen on the screw-type:

Conclusion

The most important thing to remember is that some materials are better suited for ornamental fastening, while others can withstand outside construction. If you're a newbie, remember that the most common and worst error newcomers make is choosing the wrong screw material. As a result of reading and learning from this article, you will be more aware of the fundamental distinctions between screw types, which will help you avoid undue wear-off and corrosion.