Have you found your iron pipelines leaking, squeaking, and eeking out the last dregs of their strength? If your plumbing has fallen victim to time or impairment, better replace it before you're drowned in water and debt. Your best bet is to ditch the metal pipes of the past and stick with plastic instead.

While any pipe could transport water, PVC and CPVC pipelines suit specific places and purposes better than any other. PVC pipes provide residential structures with a cost-effective option that prevents waste from infiltrating their water supplies. CPVC, meanwhile, allows industries dealing with chemicals and scalding liquids to keep their operations running smoothly.

Whichever plastic you pick should depend on the scope and objective of your project. Understanding the distinct advantages and drawbacks that each material inherently possesses can help homeowners make a confident – and correct – purchase.

What is Plastic Piping?

While metal piping may have locked homeowners in its vice grip for many a century, plastic has recently overtaken the industry. Modern-day plumbers now seek to swap out the rusted remnants of the past and replace them with plastic models.

Although their metallic counterparts have relinquished their relevance, not any plastic pipe can replace them. Plumbers must determine the most ideal installation option from amongst countless choices. From this prolific list of possibilities, two stand out amongst the rest: PVC and CPVC.

What is PVC?

Polyvinyl chloride, more commonly known as PVC, is a popular form of plastic used in both construction and in plumbing. In comparison to its less desirable alternatives, PVC stands as the third most used plastic throughout the entire world.

Despite its status as a plastic product, PVC has dealt no significant damage to our environment. The consistent recycling of these materials – up to half a billion pounds back in 2011 – keeps our atmosphere clean.

What is CPVC?

Chlorinated polyvinyl chloride, or CPVC, shares its plastic roots with its PVC counterpart. However, as its name suggests, this product contains a higher concentration of chlorine.

With a composition of 63-69% chlorine, CPVC can withstand temperatures that would make PVC buckle. Not only that, but these added chemicals fend off bacteria from accumulating inside the pipes and wreaking havoc on your home. (Related: How Much Does It Cost To Repipe A House In 2022?)

Uses of Plastic Piping

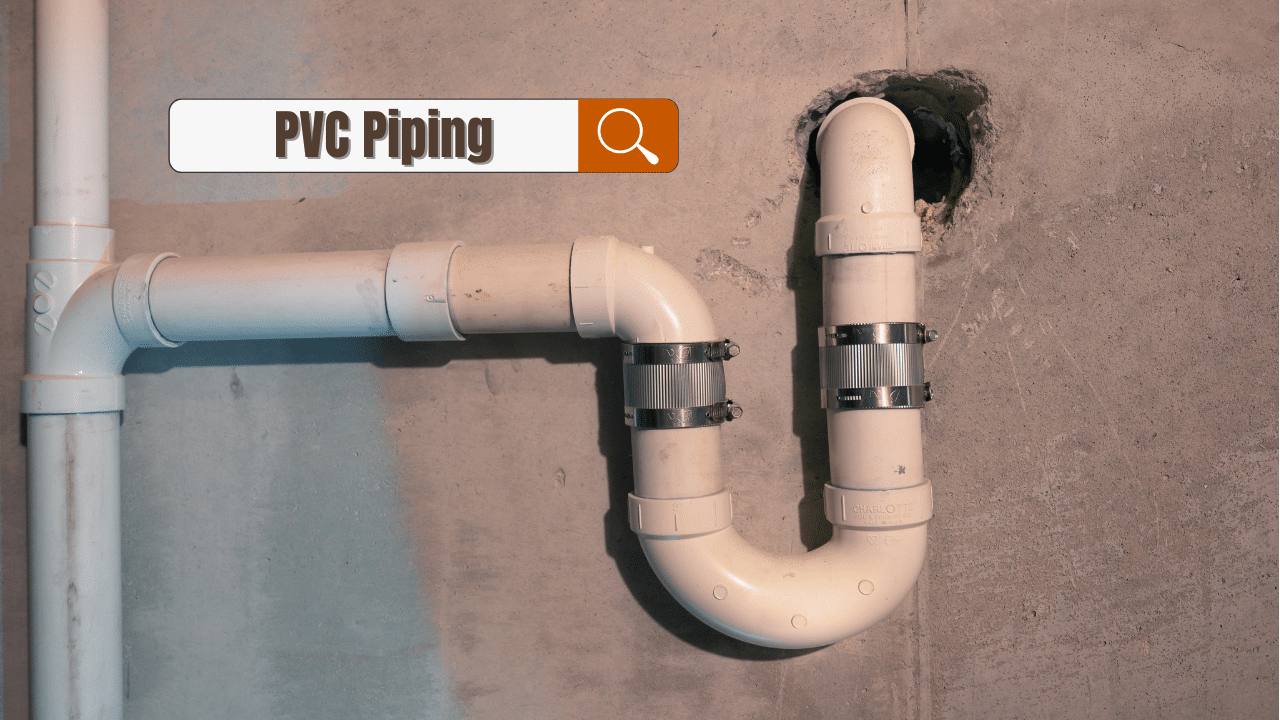

Uses of PVC Piping

As with any pipe, PVC allows water to flow in and out of buildings as needed. While pipes can service any type of structure, PVC acclimates itself most readily to residential settings.

Specifically within these spaces, PVC functions at its prime when transporting cold water in and out of the household. No matter the temperature of its contents, no water in PVC piping should exceed 140º F. Any hotter and the plastic itself can melt, releasing harmful chemicals into the surrounding area.

Thankfully, the ordinary home does not require temperatures above this, as any hotter would scald one’s skin. Water heaters, on average, can produce water between 120 to 140º F. Keep yours in its regulated region and all should stay safe.

Commercial or industrial settings, on the other hand, may require boiling water to conduct their business. In these scenarios, PVC piping becomes ineffective – and even dangerous. When properly installed in one’s home, PVC piping removes wastewater from sinks, baths, and other bathroom appliances. Once the waste has evacuated the premises, it is then transferred to local sewage and drainage systems.

This structure, known as the Drain-Waste-Vent System (or DWV), does more than keep contaminants out of your water supply. Whenever water is not already flowing through them, these pipes remove dangerous gases from one’s home instead. This system consistently assesses the air quality of its local atmosphere and adjusts accordingly to optimize its conditions.

Uses of CPVC Piping

While PVC has its roots in residential districts, that does not mean it alone dominates the market. Certain homeowners insist on the added protection or distinct aesthetic of PVC piping instead. Either pipe can provide the same services, but CPVC possesses an additional safety net when it comes to heat.

CPVC has one additional usage in residential plumbing systems that further separates it from PVC: forming fire sprinklers. When a fire breaks out, the system designed to subdue it cannot risk melting from the heat. With property fires escalating to 1100º F, the extra resistance CPVC piping affords you could save your house from incineration.

This increased tolerance to heat lends itself to CPVC’s preferred place of installation: industrial structures. Whether a business plans to process minerals, treat water, or generate electricity, the heat needed exceeds PVC’s capabilities.

Even certain commercial industries require excessive heat in order to function on a daily basis. Commercial kitchens have recipes that call for boiling water, while hospitals have to disinfect every fabric with scalding liquid. Only CPVC can meet the needs of these specific projects.

Physical Properties of Pipings

Despite their similar chemical compositions, these two plastics bear distinctive visual and physical attributes. The untrained eye could still easily mistake one for the another. Understanding which feature denotes each type of pipe will allow homeowners to feel confident in their imminent purchase.

Still uncertain as to which you’ve picked? Take another look at the pipe itself and search for any sign of ink. PVC and CPVC manufacturers alike print their respective information directly onto their products.

Physical Properties of PVC Piping

No matter the color scheme of your home, PVC piping comes in neutral tones to match any decor. Schedule 40-sized PVC piping comes in pure white, while Schedule 80-sized PVC piping accents rooms in dark gray.

Have you spotted purple pipes in the past? Plumbers primarily utilize purple PVC for landscaping projects and irrigation canals. These denote pipes that recycle or reclaim unclean water from the environment – best to keep them far from your homestead.

PVC comes in two basic forms: rigid and flexible. Rigid pipes can endure greater bouts of physical damage and ultraviolet radiation than their malleable counterparts. Flexible piping, on the other hand, performs better when used for insulation or electrical wiring. For construction that requires sterility or consistent cleanliness, such as in a hospital, prioritize flexible piping.

PVC piping comes in one uniform size, known as Nominal Pipe Size (or NPS). North American plumbing has used this as the standard form of measurement since 1927, when it replaced Iron Pipe Sizing.

Thankfully, no matter which type of PVC you utilize, no smell will pervade the surrounding area. PVC pipes are entirely odorless – unless they burn. The hydrochloric acid released upon incineration can damage your lungs and skin, so keep the pipeline away from fire hazards.

So long as they suffer no heating damage, PVC pipes can last upwards of 100 years. Even models at this age showed no difference in functionality. This allows for homeowners to install them once and move onto other projects without fear of future repairs or replacements.

Physical Properties of CPVC Piping

Unlike PVC’s standardized form of measurements, CPVC comes in two distinct sizing styles. Certain pipes utilize the NPS system shared with their PVC counterparts. However, given that CPVC frequently replaces copper piping, they use one other, appropriately-named system: Copper Tube Sizing (or CTS).

Whereas PVC piping sticks to neutral tones, CPVC veers off the beaten path to provide a wider array of colors. CPVC offers an off-white tone for its standard piping. However, NPS-sized CPVC pipes stick to a light gray tone while CTS resembles the yellow hue of the original copper piping.

Not only does CPVC come in different colors and sizes – its endurance levels differ from PVC, too. These materials each have a tensile strength, which determines how much tension they can endure before breaking.

PVC pipes have a tensile strength of 7,500. CPVC surpasses them with an average tensile strength of 8,200. This additional fortitude allows for CPVC pipes to withstand harsh environments for longer periods of time.

Along with their endurance, CPVC pipelines have extensive lifespans that can keep homeowners from worrying about repairs. The International Association of Certified Home Inspectors (or InterNACHI) discovered that CPVC can last up to 50 to 75 years. While still lacking in comparison to PVC, a half-century of sustainability can keep your plumbing protected throughout your lifetime.

PVC vs. CPVC Piping: Which to Choose?

Whenever a project looms on the horizon, the urgency to select a product increases all the more. However, these two plastics cannot be used interchangeably – each has fields they thrive in and areas they fall flat. Knowing the proper arena for each plastic can lead to less confusion and frustration down the line.

You may be wondering: can you combine both PVC and CPVC piping together? While the units themselves can attach to one another with little issue, their compatibility ends there.

PVC and CPVC piping possess different pressure and temperature ratings. This provides for uneven regulation of liquids and gases passing through them. That issue aside, the adhesives utilized for both types of pipe differ drastically.

No homeowner should ever fuse these two types of pipes together – for the pipes’ sake and for yours. Instead, stick to a single type dependent upon the project’s individual requirements.

When to Choose PVC Piping

Strapped for cash but in desperate need of home improvement? PVC piping provides a cost-efficient solution to homeowners in a pinch. With an average price of $0.75 per square foot, you can buy more materials on a minimal budget.

As opposed to those renovating businesses or factories, homeowners will make the most use of every inch of pipe. Houses have a greater need for the amenities that PVC piping provides than commercial or industrial centers do.

If you’re working on a project that relies on the transportation of cold water, then PVC is the perfect choice. Any operations that would involve water over 200º F, however, should be left to CPVC piping. These temperatures would melt PVC pipes altogether so ensure that water only reaches up to 140º F for PVC installations.

When to Choose CPVC Piping

Given the increased tensile strength and melting point of CPVC, factories and commercial structures practically demand its presence. Any building that transports water above 140º F or whose daily work puts tension on the pipes should prioritize CPVC.

Have chemicals flowing through your pipelines? Then stick with CPVC, as its increased chlorine content helps it to resist chemical damages that PVC would succumb to.

Be aware: any project with CPVC piping requires a broader budget. Prepare an average of $1 for every square foot of pipe your project entails. The stability and sustainability make the expensive price tag a worthwhile investment.