The compressor is the headquarter of the cooling unit. It’s the element that produces cool air. When it starts to slow down and requires repairs, you’ll probably want to start thinking about how much it may cost you to replace it.

According to data by HomeGuide, the average cost to replace a home air conditioner compressor is about $600 to $1,200 under warranty, or $1,300 to $2,500 when it’s not under warranty. Many HVAC contractors charge $100 to $150 per hour plus the cost of parts to repair a home AC compressor. These labor rates vary based on your location and individual contractor.

In some cases, you may have to replace the entire AC unit, and that can take 4 to 6 hours for a qualified contractor to do. A typical price range for a complete AC unit replacement is $3,300 to $6,000. The actual cost depends on the unit brand (related post: Rheem vs Trane), contractor labor rates and how long it takes to complete the job.

What is an air compressor?

Sample type of air compressor.

According to Griffith energy services, To understand how the compressor works, think about the cooling process for a split-system central air conditioner. The air conditioner pulls heat out of the air in your home, cools it over a set of cold pipes (an evaporator coil), and releases the cool air into your home. The evaporator coil remains cold thanks to a liquid refrigerant that absorbs hot air and changes it to gas. This gas is then transported outside to the condenser coil where the gas again becomes a liquid. From this point, the cycle continues.

The compressor in an AC is the part of the system that increases the pressure and temperature of the vapor refrigerant in the system. The compressor increases the pressure of the refrigerant gas in order to make the pressure difference that causes the refrigerant to flow around the system.

An adequate supply of pressurized refrigerant (sometimes known as cooling gas) is necessary for the heat exchange that takes place in the coils of the indoor and outdoor units. Without this pressurized refrigerant gas, an AC system will be incapable of producing cold air

How does the compressor fit into the picture? The compressor is responsible for moving the refrigerant between the evaporator and condenser coils, ensuring that the refrigerant changes to gas or liquid as needed. You can think of the compressor as the heart of the air conditioning system and the refrigerant as the blood. To this end, the compressor pumps the refrigerant through the system to keep it alive and running properly.

What parts can you find inside an air compressor?

The basic components of the air compressor are the electric motor, pump, and receiver. The receivers can be vertical or horizontal and have different size and capacity. An electric Motor powers the compressor pump. The motor then drives a pulley via two belts, which help in transferring power from motors to the pump pistons through a flywheel and crankshaft The flywheel fan helps cool the compressor pump.

Compressor Pump: The pump compresses the air and discharges it Into the receiver. Two-stage air compressors have a minimum of two pump cylinders. By compressing the air twice, first in a larger, low pressure cylinder, then in a smaller, high pressure cylinder, two-stage compressors can produce pressures.

The Piston: As the piston in the pump cylinder moves downward, air enters the large cylinder through the filter and air Intake valves at atmospheric pressure. On the upstroke, the piston in the large cylinder compresses the air to approximately 50 psi, and discharges it to the smaller cylinder through the intercooler tube.

The Receiver: The air is cooled using a flywheel fan this passes through the intercooler and into the smaller cylinder. In the smaller cylinder, high pressure is used to compress further to a final state. As the piston moves upward, it compresses the air and discharges it into the receiver through a check valve.

To learn more about air compressor parts, get in touch with a manufacturer right away.

Factors That May Affect AC Compressor Cost

There are a variety of air conditioning systems that you can use to cool your home — window units, portable systems, ductless air conditioners and central air conditioning systems. No matter what system you choose, they all work in basically the same way. According to The Spruce, there are five important parts to every air conditioner:

- Refrigerant

- Compressor

- Condenser

- Expansive valve

- Evaporator coil

There are a number of factors to consider to help you determine if it’s worth replacing the compressor on the AC unit or buying a whole new system:

Compressor type

Compressors come in a variety of models — single-stage, two-stage and variable-speed. The two-stage and variable-speed styles are more efficient but also cost more to replace. However, according to Compressors Unlimited, the most common types of air conditioning compressor include:

Reciprocating Air Conditioner Compressor- The reciprocating AC compressor has the longest service history and is the most similar to comparable refrigeration compressors. A piston compresses the air by moving up and down inside a cylinder. The vacuum effect created by this motion sucks in the refrigerant gas. A reciprocating AC can suffer failures related to piston wear-out, but the potential to use up to eight cylinders makes it highly efficient.

Scroll Air Conditioning Compressor- The scroll compressor is a newer innovation and consists of a fixed coil, the scroll, that makes up the unit’s center. A second coil rotates around the central scroll, compressing the refrigerant and driving it toward the center. With fewer moving parts, the scroll compressor is noticeably more reliable.

Screw Air Conditioning Compressor- Screw compressors are typically restricted to large commercial buildings with lots of air to circulate and cool. The unit contains a pair of mated helical rotors that push air from one side to the other. Screw compressors are among the most reliable and efficient around, but not cost-effective for smaller applications.

Rotary Air Conditioning Compressor- Rotary compressors are the preferred option when operating noise is a factor. They are quiet, have a modest footprint, and do not suffer from vibration as much as other compressors. In the unit, a bladed shaft rotates within a graduated cylinder to push and compress refrigerant at the same time.

Centrifugal Air Conditioning Compressor- A centrifugal AC compressor is reserved for the largest HVAC systems. As the name implies, it pulls the refrigerant in using centrifugal force. The gas is then compressed using an impeller. Because of their intended use, centrifugal compressors are among the largest and most expensive.

Brand

There are many brands to choose from, and each one provides great options for different budgets. Central AC units usually work best with a compressor from the same brand.

Refrigerant

After you replace the compressor, the refrigerant has to be filled. Refrigerant refills cost $100 to $600, depending on what kind it is — R22 or R410a.

Warranty coverage

The compressor is the main part of the AC unit. A warranty plan typically covers a significant portion of the cost to fix the compressor. If the compressor is not under warranty, it may be easier and cheaper to replace the entire AC unit.

Size

Larger units are more expensive to repair and often require more refrigerant.

Season

While no one can predict when an AC compressor might decide to break, the season is a factor when it comes to AC compressor replacement cost. Prices tend to increase during the spring and summer months when HVAC contractors are busy. Off-peak months are generally the most affordable times — January through March and September through November.

When to replace your compressor?

The typical lifespan of an AC compressor is between 10 and 15 years while your HVAC system as a whole should last 15 to 20 years.

However, this lifespan can be extended or shortened depending on how well your system is maintained, the type of operating conditions, and the location of the AC outdoor unit.

Some signs that you may need to replace your compressor include refrigerant leaks, unusual noises when the AC is turned on, and/or sporadic cooling. If you notice any of these signs, you should call a licensed HVAC professional right away to diagnose the problem before it becomes more serious and costly to repair.

(Related: Is it Worth Spending More Money on An Air Filter with a Higher Merv Rating?)

Factors That Affect Compressor Life Expectancy

According to Phyxter, there are several factors that may cause a compressor to break down over time:

Maintenance and Servicing: The principal factor determining whether your compressor carries on working as it gets older is adequate upkeep and proper maintenance. There are specific actions that you, as a homeowner, can take to look after the health of a compressor. Then, you should check the refrigerant lines and the insulation that covers them to make sure that they are in good condition. While you are doing this, you can check the drain lines for blockages, pouring a bleach solution down them to clean them.

Overuse and Underuse: A compressor contains a motor and a series of pistons that work to move the refrigerant around the refrigerant lines. Like any motor, underuse can result in the moving parts inside seizing up and stop working. It is a good idea to turn your AC on now and again, even though the colder months, to ensure that this does not happen.

Refrigerant leak: if the system is not charged with the right amount of refrigerant. The compressor, heat exchanger, refrigerant lines, and refrigerant form a closed system, and in an ideal world, you should not have to top it up with more refrigerant.

In case you were wondering, a Heat Pump compressor works exactly the same as an AC compressor. A Heat Pump has the ability to reverse its heat transfer and act as an AC and heater at the same time.

Replacing Compressors and The Cost Effect

Compressors aren't eternal. They wear and tear and like every cog in a machine, they can be replaced.

When your compressor goes out, it is almost always better to replace the whole condensing unit. However, some parts can easily be replaced to keep your outdoor unit running longer.

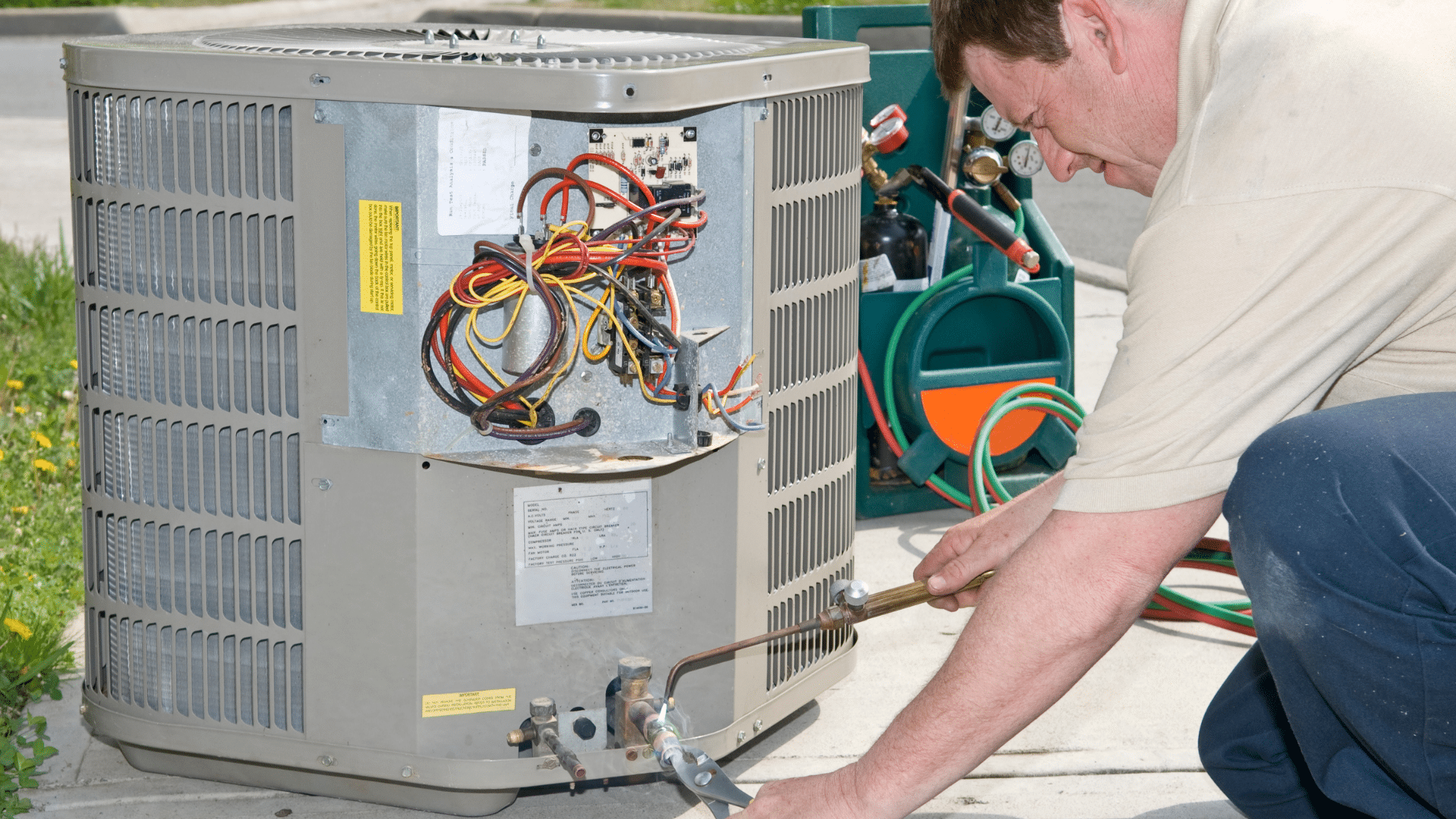

Image of a man repairing an AC compressor.

Repair Cost

If your compressor is still working but is not running efficiently, a technician may be able to tune up your HVAC, so you do not have warm air coming out of your vents. Something as simple as a malfunctioning capacitor or a refrigerant leak could be causing your problem.

An air conditioning repair company will charge you between $200 and $400 to repair either issue. A refrigerant leak may be more costly depending on the amount of refrigerant the contractor has to replace and the type your system uses.

Parts Cost

The cost of compressors or condenser units is similar. You can find them for as little as $600 or more than $3,000. Here are some other parts you may need to replace when your compressor breaks down:

- Fan motor ($300 to $600)

- Capacitor ($10 to $200)

- Condenser coil ($400 to $1,200)

- Evaporator coil ($700 to $3,000)

- Installation Cost

The installation cost is typically equal to the cost of the new unit. You can expect the job to take at least 8 hours to complete at a rate between $50 and $150 per hour.

(Source: Review Home Warranties)