If you want to ensure a flawless tile installation, the key is to follow the best practices according to the tile industry standards. (Related: Tile Installation: A Cost & Consumer Guide)

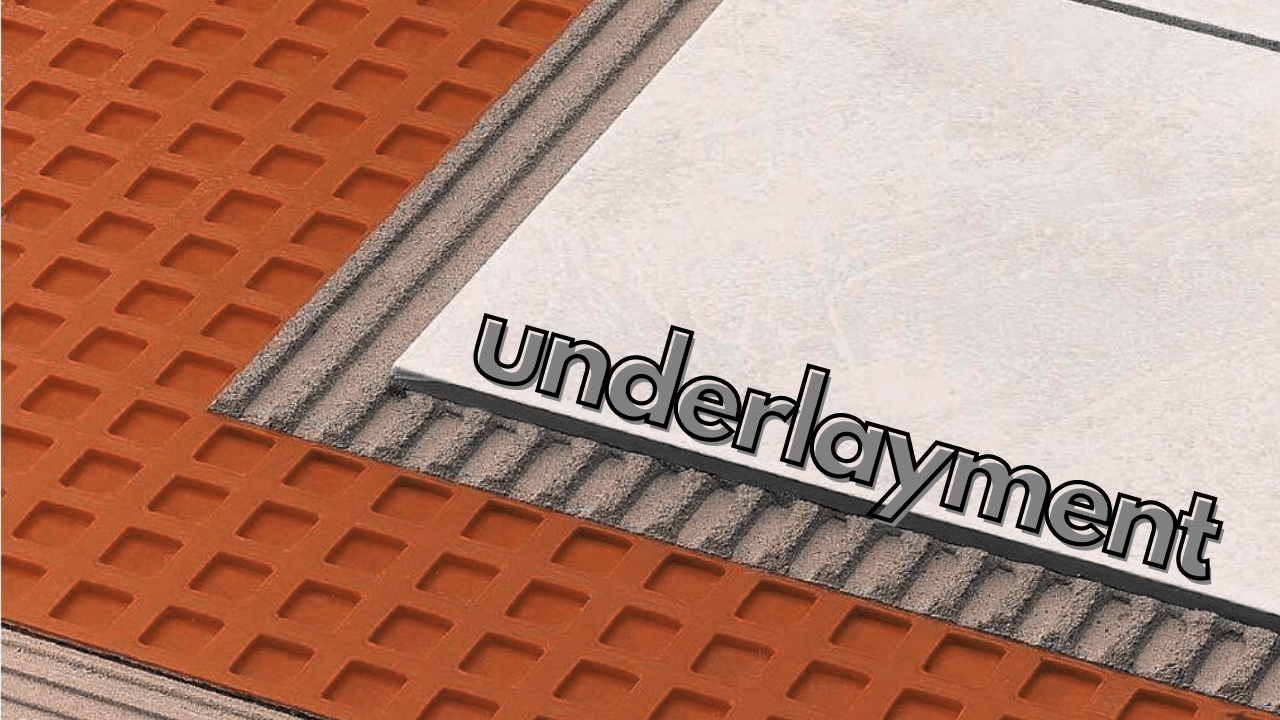

Remember, this usually boils down to the foundation– where the underlayment can make or break your tile installation project.

Let's dive into detailed insights from an underlayment expert to ensure a flawless installation project.

What is an Underlayment?

Underlayment is a crucial addition to conceal any subfloor imperfections. Additionally, it improves the protection of the floors, reduces any noise, and gives you a level, uniform base on to install your new floors on.

Regardless of your chosen flooring material, an underlayment is essential for durability, performance, and visual appeal.

Most underlayments are composed of several layers: a floor cover, a strong subfloor, cement or concrete for support, and a soft felt or carpet barrier.

Underlayment for Tiles

Undoubtedly, tile flooring is famous for bathrooms and kitchens because of its water resistance.

There's also a wide variety of tile designs in the market today, in every color and style you can ever imagine. When it comes to underlayment needs, tiles require strong underlayment support to prevent them from cracking, given heavy foot traffic.

Tiles also need to remain flexible to absorb contraction and expansion in fluctuating humidity and temperature environments.

Best Underlayment Material for Tiles

Generally, two primary underlayment materials are best suited with tiles.

First, the Cement Board Underlayment (CBU) is composed of wood or cellulose fibers. The material is known to reinforce cement effectively. Fibers improve the flexibility of the underlayment– protecting them from cracking under pressure. Most cement boards are commonly glued, nailed, or screwed into your subfloor.

Next, there's the DITRA Uncoupling Membrane, made from polythene. It is considered a premium overlay featuring beautiful grid-style square cavities. The mortar sticks to the tiles after it hardens, forming a solid base.

DITRA material enables tile contraction and expansion, giving you an effective moisture barrier. It can also be used on concrete, wood, and radiant heated floors.

Choosing the Suitable Material for your Project

Choosing the suitable material for your tile project will significantly depend on any present issues upon assessing the current condition of the subfloor or substrate.

Here are some guide questions to keep in mind:

If your floor surface is not level enough to meet tile industry standards– you're likely to stumble across several problems if left unaddressed. That said, this is one crucial factor to ensure before pushing through with your project.

Three Types of Underlayment for Tile

Let’s discuss the three main types of tile underlayment, as it may either make or break your project’s success.

Pro tip: It's crucial to stay updated with all the advancements in tile underlayment tiles as you'll find out these are ever-changing with several brand-new products in no time.

1. Backer Boards

The backer board category has been around as early as the 1970s. It has since revolutionized the tile industry by giving a tile-ready surface in sheets/panels for ceiling, floors, and walls.

Here are some materials officially considered as Backer Board by The Tile Council of North America (TCNA).

Usually, the floor area covered by a backer board is often irregular or wavy. To correct this, you will need to flatten the site accordingly. Note that this is a crucial factor, given that the patch is placed under the board– not on top.

2. Floor Underlayment Preparation Materials

Ideally, any surface irregularity must be corrected for this project. In most cases, contractors use a troweled-on patch or self-leveling underlayment (SLU) to achieve a floor/wall surface that’s even enough for tile installation.

It boils down to three subtypes: Underlayments, Trowelable, and Poured as per The National Tile Contractors Association (NTCA).

Let’s discuss the different subtypes in detail:

Additionally, poured underlayments can be classified into one of two categories:

- 1Gypsum-Based Underlayments - These are often used with resilient flooring to fix small cracks or holes. In some cases, these are also used to flatten large concrete/wood floor areas or solve other related subfloor issues .Depending on your manufacturer's recommendations, you can mix gypsum-based underlayment with water or latex additives.

- 2Cement-Based Underlayments - Pourable self-leveling underlayments (SLU) contain aggregate, cement, and chemical additives. This improves the material's flowability and strength. Most substrates treated with latex additives have two primary functions: increasing the bond strength and priming the substrate. The latter equalizes the substrate's absorption rate– eliminating any hot spots that may dry out the underlayment.

3. Membranes

Lastly, membranes are the third type of underlayment for tile use. Here are the different membrane types below:

What's the Right Underlayment for Tile on Concrete?

The thing is, you can use a combination of the products we mentioned above to achieve a suitable surface for your tile installation project.

For one, you may opt to flatten the floor using a patch or SLU. The surface may also benefit from the many advantages of any backer board or membrane type.

Nonetheless, underlayments serve their purpose primarily due to how manufacturers push for innovative products in the market. This allows you to achieve a flawless tile installation project, sufficiently even/level and free of lippage (vertical displacement).

Always strive to follow any guidelines issued by your manufacturer. When looking for local contractors, prioritize those with proper certifications to ensure a high-quality tile installation.

Using the proper underlayment for your tile project can make it a success. The first step starts with ensuring concrete slab readiness.